Major Project

A device which eliminates the effects of Target Panic in Archery [Read more]

Major Project: A device which eliminates the effects of Target Panic in Archery

The product is a finger tab, worn by an archer when they are shooting a recurve bow. The tab has 3 force sensor resistors underneath the bowstring to measure the archers draw force at any time, and is also used to map the pressure distribution over the fingers. A plate over the archers fingers is added, which only opens at an appropriate time in the archers draw. This encourages consistent shooting and helps the archer to regain control over the shot. The tab promotes a positive archery technique through design for behaviour change, with a back-plate and translating finger spacer. The tab is adjustable, with a one-size-fits-all selling point to reduce stock levels in store.

Major Project: The problem where an archer with Target Panic does not have control over their shot routine

It is estimated that 90% of all archers will experience Target Panic during their archery career. Target Panic is a lack of control over a shot, leading to inconsistencies and lower scores in competition. Symptoms include a lack of aiming, not reaching the 'anchor' point on the face, and/ or releasing the bowstring prematurely. The product solution does not allow the archer to release the bowstring until these actions are completed, hence re-establishing control over the shot. The product is set-up, calibrated and monitored using a mobile app.

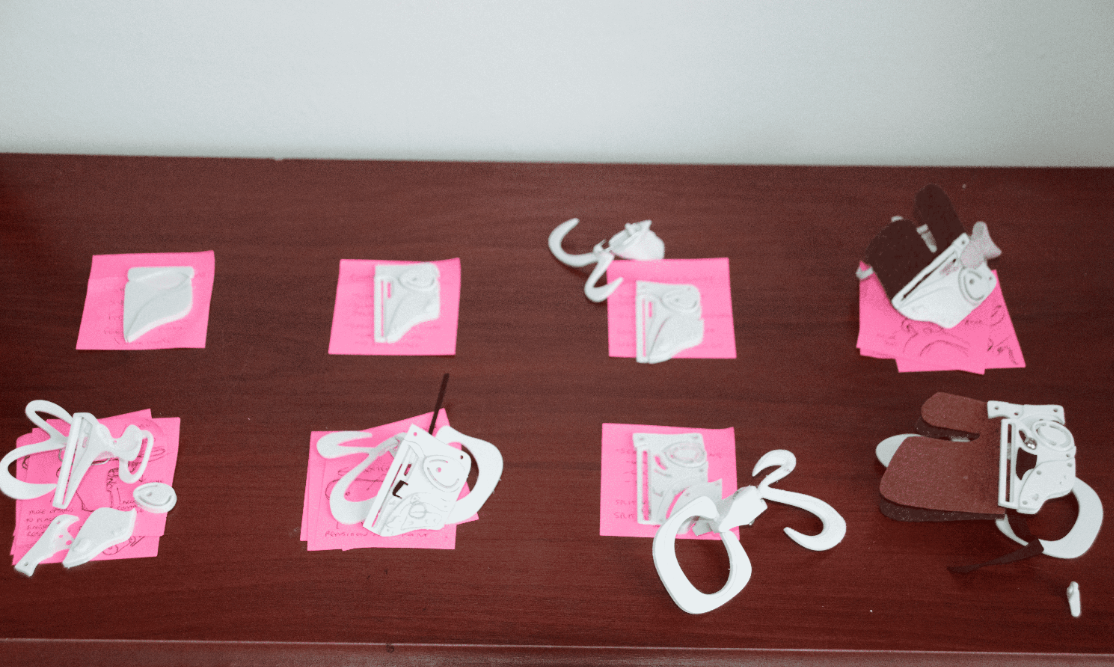

Major Project: A series of prototypes in the early stages of development

Research focused on the technical aspects of the product to ensure features were fit for purpose. Interviews were conducted online with target users. Coaches, industry experts and an Olympic archer were also consulted with regards to the tabs function, style and aesthetic. The design was iterated for optimisation.

3D CAD Project: A 3D Printed Computer Mouse with working buttons and scroll wheel

The brief offered the opportunity to design for 3D print. This enabled the design of intricate parts, delicate structures and surfaces which would otherwise be impossible to create. The product solution included complex structures and ergonomic handling, with the target market being 11-31 year old computer enthusiasts.

3D CAD Project: Different CAD packages were used to create the product

The CAD process involved sub-divisional surface modelling, inclusion of tolerances, and tactical placement of parts such as the laser in the PCB for smooth mouse movement. Both Speedform and Solidworks were used due to their relative strengths and weaknesses.

Digital Fabrication Project: A novelty phone dock and case which involved a remote control car

A brief was given to design a CNC machined phone dock and 3D printed phone case, with the added challenge of providing additional functions, and to be stylised to work as a pair. The proposed design is a novelty gift for 4-24 year olds, with a working remote control car acting as the dock.

Digital Fabrication Project: The phone case and dock both have multiple functions

The product makes use of machining capabilities, with optimised machining time and minimal waste. A full, working prototype was produced and colourised accordingly.

Georgiana Jones

I am a goal driven designer who thrives in a continually changing environment. I have strong appreciations for the functional, economic and environmental implications of a product or design.

I have degrees in both Aeronautical Engineering (BEng, 2019), and Integrated Industrial Design (MSc, 2020), accompanied by a year in Industry. This unique combination of studies gives me a fresh perspective, powering my application of lateral thinking which helps to identify, analyse and creatively solve a range of technical and design related problems.

My strengths lie in design optimisation (DFM/ DFA), material and process selection, and attention to detail. I am proficient in 3D CAD and visualisation, and enjoy the hands-on approach of prototype creation.

I thrive in a continually changing environment, with eventual ambition to travel and explore in a challenging but creative workplace beyond the UK.

Major Project

A device which eliminates the effects of Target Panic in Archery

Awards

British Model Flying Association Payload Challenge (2016), top 10 finish. This is an extra-curricular competition where a team of 5 design and prototype a remote controlled aircraft, to specifications given in a brief. This competition is open to applicants across both the UK and the rest of Europe.

Engineering Education Scheme Wales (2015), best overall written report. This was a project where our team of 3 designed and produced a product to record unsafe behaviours at UK level crossings. The product consisted of a camera which was activated by a broken infrared beam every time a person or car crossed a specific point within the area of interest. The product was controlled by a Raspberry Pi and coded in Python.